Food Industry

Utilizing Valves & Ejectors in the Food Industry

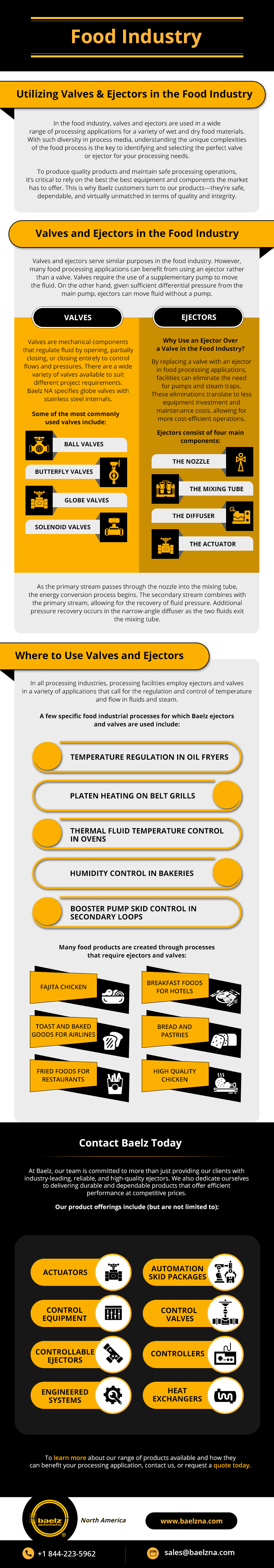

In the food industry, valves and ejectors are used in a wide range of processing applications for a variety of wet and dry food materials. With such diversity in process media, understanding the unique complexities of the food process is the key to identifying and selecting the perfect valve or ejector for your processing needs.

To produce quality products and maintain safe processing operations, it’s critical to rely on the best the best equipment and components the market has to offer. This is why Baelz customers turn to our products—they’re safe, dependable, and virtually unmatched in terms of quality and integrity.

At Baelz, we offer an extensive catalog of products suitable for use in the food industry. Customers use our products to help control heat, flow, and pressure in processing operations.

Valves and Ejectors in the Food Industry

Within the food processing applications both valves and ejectors are utilized in the same the same manner, but they function in different ways. They employ different operating mechanisms and offer different advantages and best use cases.

Valves

Valves are mechanical components that regulate fluid by opening, partially closing, or closing entirely to control flows and pressures. There are a wide variety of valves available to suit different project requirements. Baelz NA specifies globe valves with stainless steel internals.

Some of the most commonly used valves include:

- Ball valves

- Butterfly valves

- Globe valves

- Solenoid valves

Ejectors

Why Use an Ejector Over a Valve in the Food Industry?

In the food industry, valves and ejectors serve similar purposes. However, many food processing applications can benefit from using an ejector rather than a valve. Valves require the use of a supplementary pump to move the fluid. On the other hand, given sufficient differential pressure from the main pump, ejectors can move fluid without a pump.

By replacing a valve with an ejector in food processing applications, facilities can eliminate the need for pumps and steam traps. These eliminations translate to less equipment investment and maintenance costs, allowing for more cost-efficient operations.

Ejectors consist of four main components:

- The nozzle

- The mixing tube

- The diffuser

- The Actuator

As the primary stream passes through the nozzle into the mixing tube, the energy conversion process begins. The secondary stream combines with the primary stream, allowing for the recovery of fluid pressure. Additional pressure recovery occurs in the narrow-angle diffuser as the two fluids exit the mixing tube.

The basic operating mechanism of all ejectors relies on principles that stem from the Bernoulli equation and Venturi effect. At Baelz, our ejectors leverage these principles in a more sophisticated design to ensure a more efficient and reliable performance in all processing applications. These qualities can result in significant savings for our customers.

Where to Use Valves and Ejectors

In all processing industries, processing facilities employ ejectors and valves in a variety of applications that call for the regulation and control of temperature and flow in fluids and steam.

A few specific food industrial processes for which Baelz ejectors and valves are used include:

- Temperature regulation in oil fryers

- Platen heating on belt grills

- Thermal fluid temperature control in ovens

- Humidity control in bakeries

- Booster pump skid control in secondary loops

Many food products are created through processes that require ejectors and valves:

- Fajita chicken

- Breakfast foods for hotels

- Toast and baked goods for airlines

- Bread and pastries

- Fried foods for restaurants

- High quality chicken

Contact Baelz Today

At Baelz, our team is committed to more than just providing our clients with industry-leading, reliable, and high-quality ejectors. We also dedicate ourselves to delivering durable and dependable products that offer efficient performance at competitive prices.

Our product offerings include (but are not limited to):

- Actuators

- Automation skid packages

- Control equipment

- Control valves

- Controllable ejectors

- Controllers

- Engineered systems

- Heat exchangers

Since 1986, we have provided customers with the highest quality products. With the addition of Baelz North America, we can provide North American customers with local representation and shorter lead times.

To learn more about our range of products available and how they can benefit your processing application, contact us, or request a quote today.